VS Line

1,00€

The RIBO three-phase industrial vacuum cleaners of the VS line are specifically designed to be used in harsh working conditions requiring sturdiness, manoeuvrability and low noise levels.

They are able to stand intensive and continuous use even 24 hours a day, maintaining an exceptionally long life cycle and ensuring high performance and reliability at the highest level.

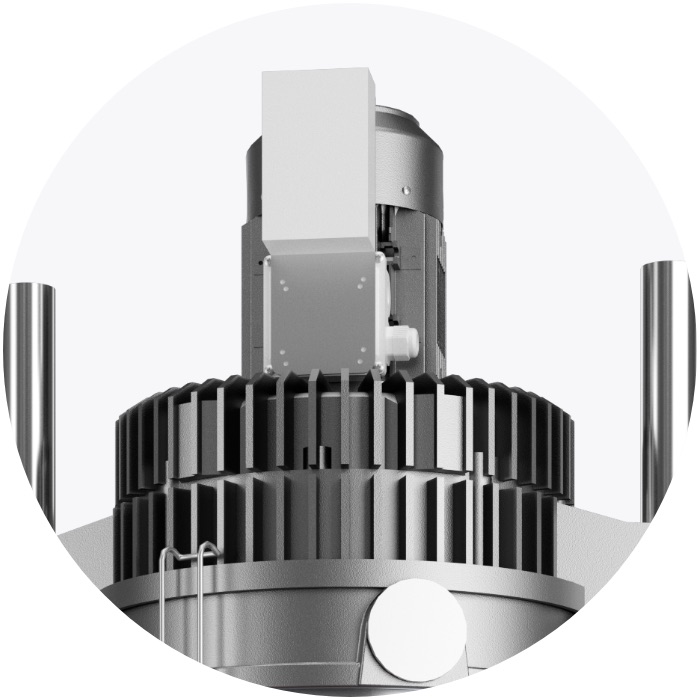

The RIBO three-phase industrial vacuum cleaners of the VS line are extremely versatile devices, which can be used in all industrial sectors, both for cleaning and maintenance operations and also during production. They are compact machines, thanks to the motorization located on top of the vacuum cleaner, and extremely flexible and agile inside production facilities. The VS10 and VS20 systems, thanks to their suction power, are also suitable to be used as centralised vacuum systems on large installations.

The components modularity of the RIBO’s three-phase vacuum cleaners makes it possible to offer models with different filter systems and collection capacities, so that they can be used for suctioning:

- swarf, liquids and scraps in general, even mixed with oil, from all mechanical processes, guaranteeing maximum cleanliness of machine tools and machining centres

- scraps and trimmings from automatic machines and packaging machines

- bakelite dust (even very fine dust), graphite, plastic material, etc., generated by cutting, drilling, contour cutting, brushing, grinding and any other type of work processing

- dust, sand, gravel, cement, etc. from foundries, construction sites, quarries, paint plants, ceramic industries, automotive and transport industries in general for removal and recovery of materials

The VS range of vacuum cleaners is available from 0.5 kW to 15 kW in the following versions:

- VS0,5: for dust and dry solid materials on fixed installations and with a particularly small dimension

- VS3/100-AV: for dust and dry solid materials on fixed installations (automatic machines and pneumatic conveyors)

- VS3/139 – VS5/139 – VS10/439 – VS20/639:

- for dust and dry solid materials (centralised systems, automatic machines and pneumatic conveyors) – for extracting small amounts of not particularly dusty material.

- VS3/159 – VS5/159 – VS10/459 – VS20/659: for dust and dry solid materials with a two-stage filtering system

- VS3/179 – VS5/179 – VS10/479 – VS20/679: for liquids and swarf, also mixed with oil (machine tool and workshop cleaning)

- VS3/199 – VS5/199 – VS10/499 – VS20/699: for fine dust and dry solid materials – suitable for large quantities of fine material (fibreglass dust, graphite, calcium carbonate, silica, flours, stearates, etc.).

All models are available in stainless steel, with a pneumatic cyclic filter cleaning system (FAC), with a multi-stage filtering system for high-efficiency collection of fine dust, including toxic and/or harmful dust (FAS), and in compliance with the ATEX directive, in Group II, Category 3G/D, for use in areas classified 2.22.