-

Ribo Evolution

Ribo EvolutionCustomised suction solutions for the pharmaceutical industry

Read moreIn the pharmaceutical industry, cleanliness and safety in the production environment are paramount. Every step of the process, from manufacturing to packaging medications, requires high-quality equipment that ensures maximum control of waste particles. In this context, RIBO’s vacuum solutions meet the specific needs of the pharmaceutical sector, offering reliable performance and dedicated design support.

-

Ribo Evolution

Ribo EvolutionSuction solutions for electrical cable production

Read moreThe production of electrical cables is a highly specialized process that requires advanced technologies, not only to ensure high production efficiency but also to maintain high standards of quality and safety. One of the key needs in this process is the effective suction of waste and dust, particularly during the talc application phase.

-

Ribo Evolution

Ribo EvolutionSuction solutions for the commercial aviation industry

Read moreIn the complex and innovative aviation industry, the production and assembly of large structural components requires highly specialized processing, which inevitably generates waste and scrap that must be managed with maximum efficiency. Proper management of these materials is essential to maintaining a safe and clean work environment, as well as ensuring the quality of the final products.

-

Ribo Evolution

Ribo EvolutionSuction solutions for coatings and surface treatments for metals and aluminum

Read moreIn the aluminum surface and coating manufacturing industry, effective waste and dust management is a crucial issue. Machining operations generate fine dust, toxic residues and abrasive materials that can pose a serious risk to both the health of operators and the environment. To maintain a safe and productive work environment, the adoption of reliable industrial vacuuming solutions is essential.

-

Ribo Evolution

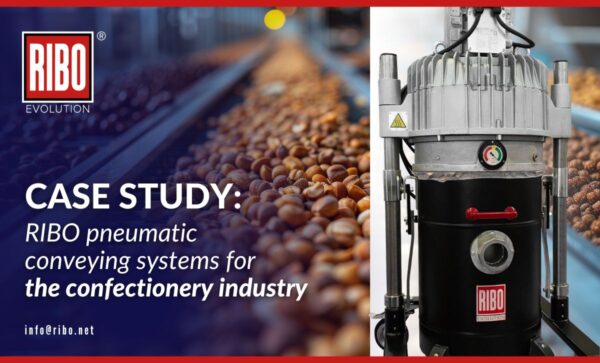

Ribo EvolutionRIBO pneumatic conveying systems solutions for the confectionery industry

Read moreIn the confectionery industry, a significant amount of dust is generated during the conveying and processing of hazelnuts, and it is important to separate impurities while improving the quality of the ingredient. Suction systems can be equipped with filters and separators that effectively remove foreign particles, improving the quality of the final product. RIBO offers state-of-the-art suction and pneumatic conveying solutions to meet these specific needs.

-

Ribo Evolution

Ribo EvolutionSuction solutions for the aluminum extrusion process

Read moreIn the production of aluminum window and door systems, it is crucial to ensure efficient operation and superior quality of the end product. This need becomes particularly evident in the extrusion industry, where handling large volumes of aluminum chips and dust is a significant challenge.

-

Ribo Evolution

Ribo EvolutionSuction solutions for the domestic and professional cleaning sector

Read moreIn the vast landscape of the detergent industry, it is essential to ensure the quality and safety of products by adopting suitable cleaning operations. In this article, we will explore the importance of industrial vacuuming in this industry, focusing on a case study of a company specializing in the design, development and production of liquid detergents for domestic or professional use.

-

Ribo Evolution

Ribo EvolutionCustomized suction solutions for the paint, coatings and inks industry

Read moreIn the manufacturing of automatic industrial dosing systems for mixing inks and paints for large companies and tinting systems found in hardware stores and color centers, effective waste management at every stage of production is critical to ensure a safe working environment and the quality of the final products.

-

Ribo Evolution

Ribo EvolutionSuction solutions for the production of electronic systems for the automotive industry

Read moreIn the industrial production of electronic systems and equipment, operational efficiency and the quality of the end product are of paramount importance. One of the often underestimated issues is the management of waste during each stage of the production process.

-

Ribo Evolution

Ribo EvolutionSuction solutions for the production of metal components and industrial riveting machines

Read moreThe metalworking industry requires effective suction solutions to ensure operational efficiency, product quality and workplace safety. In this article, we will examine in detail the suction requirements of a metalworking company for the maintenance of lathe collection tanks used for the production of metal components in series and industrial riveting machines.

Posts tagged with ‘case study’

Ribo Evolution > case study