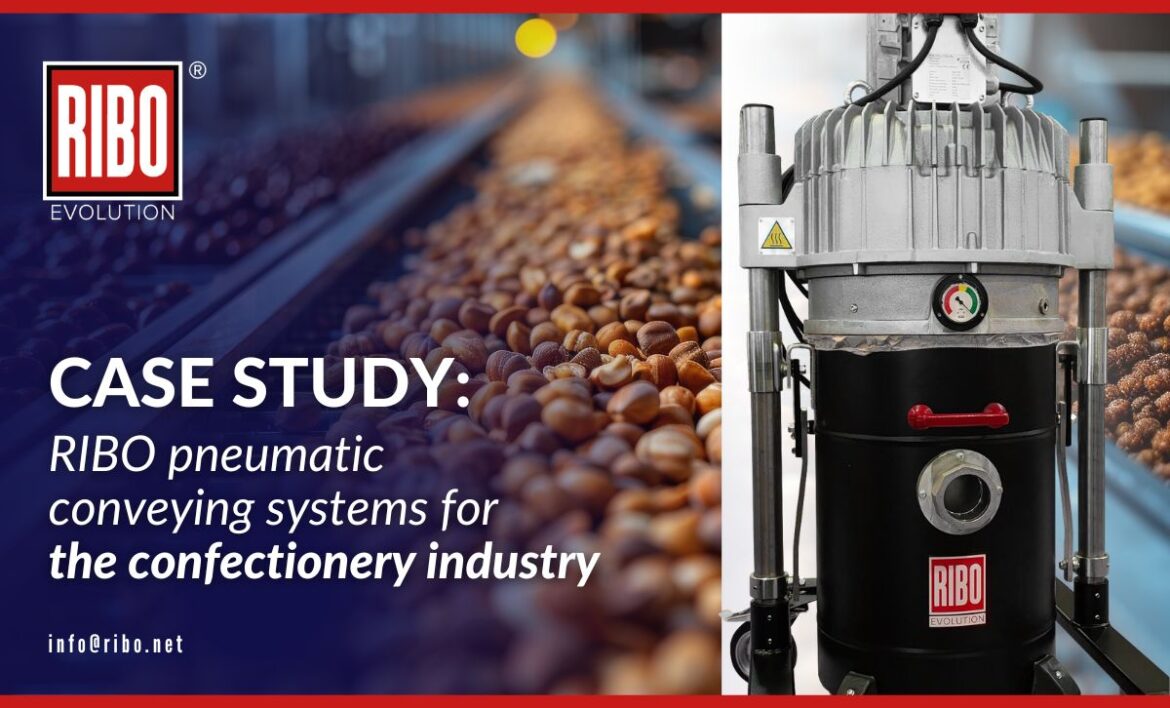

In the confectionery industry, a significant amount of dust is generated during the conveying and processing of hazelnuts, and it is important to separate impurities while improving the quality of the ingredient. Suction systems can be equipped with filters and separators that effectively remove foreign particles, improving the quality of the final product. RIBO offers state-of-the-art suction and pneumatic conveying solutions to meet these specific needs.

What are the company’s suction and material handling needs

Companies that produce confectionery products face several challenges related to the handling of materials such as raw materials, ingredients, and semi-finished products. Suction systems must be designed to facilitate regular maintenance and cleaning. This is essential to prevent residue buildup and ensure the smooth continuous operation of the conveying system. RIBO has developed a range of pneumatic conveying systems that perfectly meet the needs of the confectionery industry, specifically for hazelnut conveying.

RIBO pneumatic conveying systems for the confectionery industry

RIBO pneumatic conveyors are widely used in the confectionery industry for a number of key applications that improve operational efficiency and safety in the working environment.

Here are some of the main uses:

- Ingredient handling

In the confectionery industry, which produces chocolate products, they handle a variety of ingredients critical to the creation of their products. Pneumatic conveyors allow these ingredients to be picked up and transported efficiently, keeping work areas clean and reducing the risk of accidents and contamination.

- Transportation efficiency

Pneumatic conveyors are ideal for handling main ingredients such as cocoa, nuts and flours. This system allows materials to be moved quickly from processing points while reducing the risk of physical damage to ingredients and maintaining their integrity for further processing

- Feeding processing plants

These systems are used to feed processing equipment such as roasting machines, grinders, and mixers. Pneumatic conveying ensures a constant and smooth flow of materials, improving the efficiency of processing operations.

- Clean work environments

A clean work environment is essential for product safety and quality. Pneumatic conveying systems are designed to facilitate regular maintenance and cleaning. This is essential to prevent the accumulation of debris, reduce the risk of contamination, and ensure continuous and safe operation of the conveying system.

To meet these specific needs, the company adopted a T 2.2 50 pneumatic conveying system from RIBO.

The features of RIBO’s T 2.2 50 pneumatic conveying system

One of RIBO’s flagship products is the T 2.2 50 pneumatic conveying system for dry powders and solids, which has ideal features for the confectionery industry:

- Power and reliability

T 2.2 50 offers high suction power being equipped with a three-phase motor, ensuring consistent performance for continuous work cycles;

- Versatility

The pneumatic vacuum conveying allows rapid handling of all types of ingredients such as cocoa beans, nuts such as hazelnuts, almonds walnuts, pistachios that are roasted, used whole or chopped making efficient handling, storage and loading on roasting, mixing and dosing plants, with extremely reduced maintenance, space, time and cost;

- Ease of maintenance

It is designed to minimize maintenance operations, saving time and resources;

- Safety

It is equipped with multi-stage diversified filtration systems with manual or automatic cleaning, ensuring a clean and safe working environment, preserving the health of operators and safety in workplaces.