At the beginning

In the heart of Emilia-Romagna, a land of cattle farms and seasoned cheeses in Italy, there is a company in the dairy industry that has been producing grated cheese for over twenty years. At the beginning of their career, the founders commissioned RIBO to create a pneumatic conveying system capable of serving the two bagging and packaging lines for grated cheese. RIBO technicians have thus studied and designed a customized system consisting of a vacuum cleaner of the VS line, ideal for continuous use in severe conditions, in combination with two loading hoppers of different sizes.

“We needed a pneumatic conveying system perfectly coordinated with our bagging machines,” says the production and quality control manager. “The need at the time was to speed up and automate the production process in order to optimize the product packaging activity“.

The needs change

With the increase of work and the accumulation of experience in the field, the managers realize that it is necessary to make a change to the system. “Over time, we realized that with the system fixed to the wall, we could not easily carry out routine maintenance operations. For industries in the food sector, it is necessary to carry out frequent and thorough washing and with the wall system it was difficult for us to perform these operations. So, we contacted our RIBO representative, who listened to our new needs and proceeded to design, together with the technicians, the ideal solution for us”.

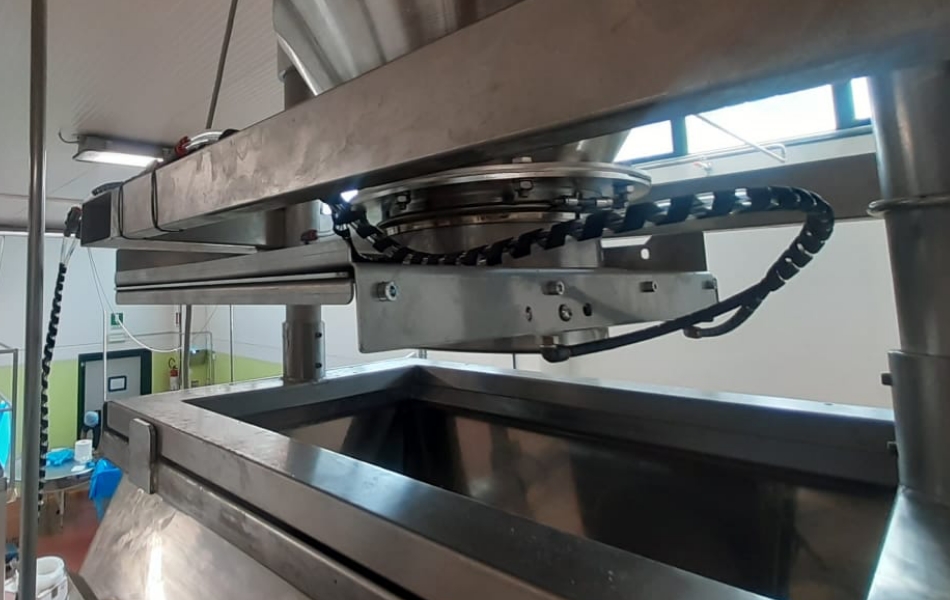

Thanks to the ability to build customized systems for the customer, RIBO technicians have made the necessary changes to meet the new needs of the dairy company. We took care of changing the installation of the hoppers from fixed to removable, to facilitate washing operations and optimize the time between machine downtime and restoration.

“Another need that we have encountered over time was to make the hoppers the same in order to be able to set the unloading of material at the same time” continues one of the managers. “RIBO technicians proved to be once again available and efficient, proposing to shorten the longer hopper in order to optimize the whole system in the best possible way”.

Not only did we make the hoppers identical, but we also updated their unloading system: the original system, in fact, had worn out over time. The weight of the product overloaded the palette unloading which inevitably collapsed under the weight of the grated cheese. For this reason, we have studied a guillotine unloading system, more suited to the customer’s needs since it solves the problem of gravity. Therefore, no waste for the company and greater system efficiency!

Quality rhymes with performance

An updated and highly performing system contributes to significantly improve the quality of the final product. For this reason, our technicians thoroughly study each application and each industrial sector, to ensure high standards of system efficiency and product quality.

In the case of our dairy company, we proposed to update the jolting system inside the hoppers. The cheese, having a high degree of humidity, tends to settle over time, stratifying and therefore making frequent washing necessary. To optimize machine downtimes, therefore, we replaced the old system with a more performing one, which prevents the cheese from settling on the walls of the hopper.

Another substantial change concerns the installation of an intermediate cyclone which, thanks to its centrifugal force, intercepts the cheese particles, that are coarser and of lower quality, and discharges them into a stainless steel container. This process is essential to increase the quality of the product.

“We are extremely satisfied with the upgrade of our pneumatic conveying system,” say the managers. “In this way we are able to optimize the production process and obtain a superior quality product. The RIBO technicians are always at our disposal for any request: we could not ask for better support! “.